6.2.5. Processes¶

6.2.5.1. Description¶

Here you can define general parameters of the process:

- short name and description for the process

- heating or cooling

- unit operation type (classification of the process; optional)

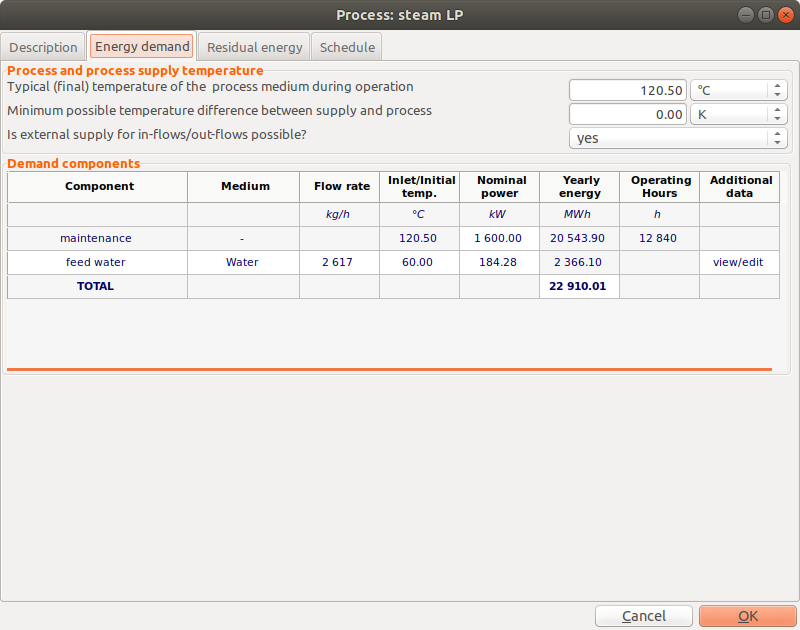

6.2.5.2. Energy Demand¶

Here you can define

- the process temperature

- the minimum temperature drop between supply and process medium (0 if the suppy medium is directly used in the process, without heat exchanger)

- possibility of external preheating / -cooling for in- and outflows (in the case of external preheating: the minimum temperature drop will not apply for in- and outflows. Temperature drop there will be defined by the individual heat exchangers)

By right-clicking in the table you can add / delete components of energy demand:

- maintenance heat / cooling demand: energy demand at a constant temperature level

- inflow: medium entering the process that has to be heated / cooled

- start-up: thermal mass that has to be heated / cooled at the beginning of each process operation cycle

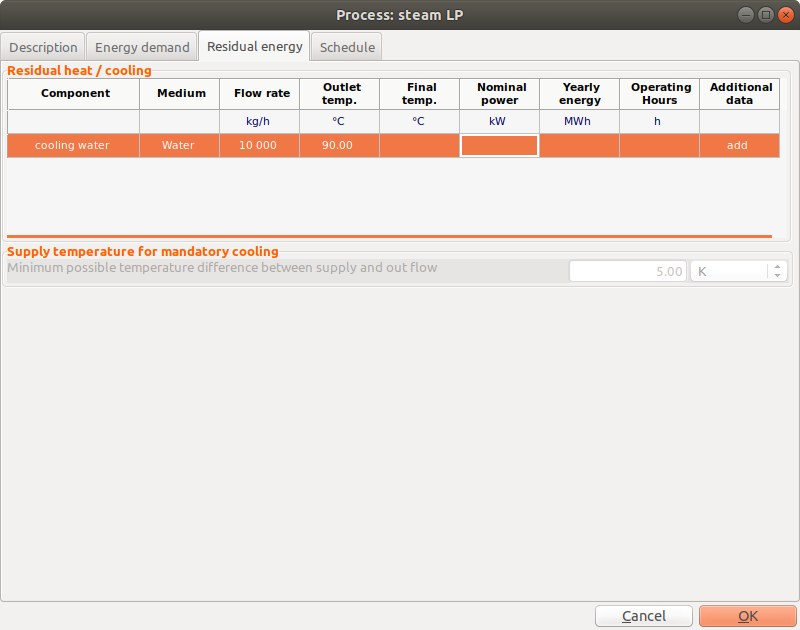

6.2.5.3. Residual Energy¶

By right-clicking in the table you can add / delete outflowing streams (waste heat / cooling):

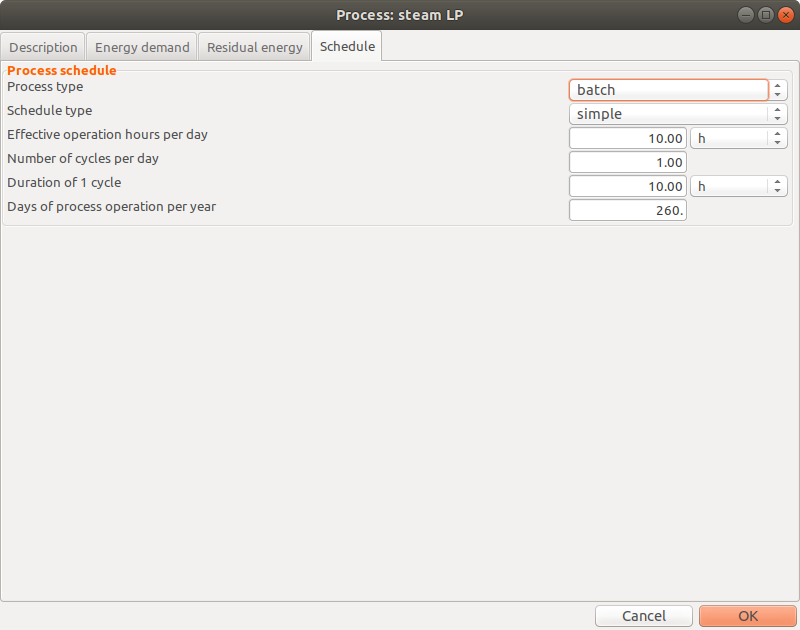

6.2.5.4. Process Schedules¶

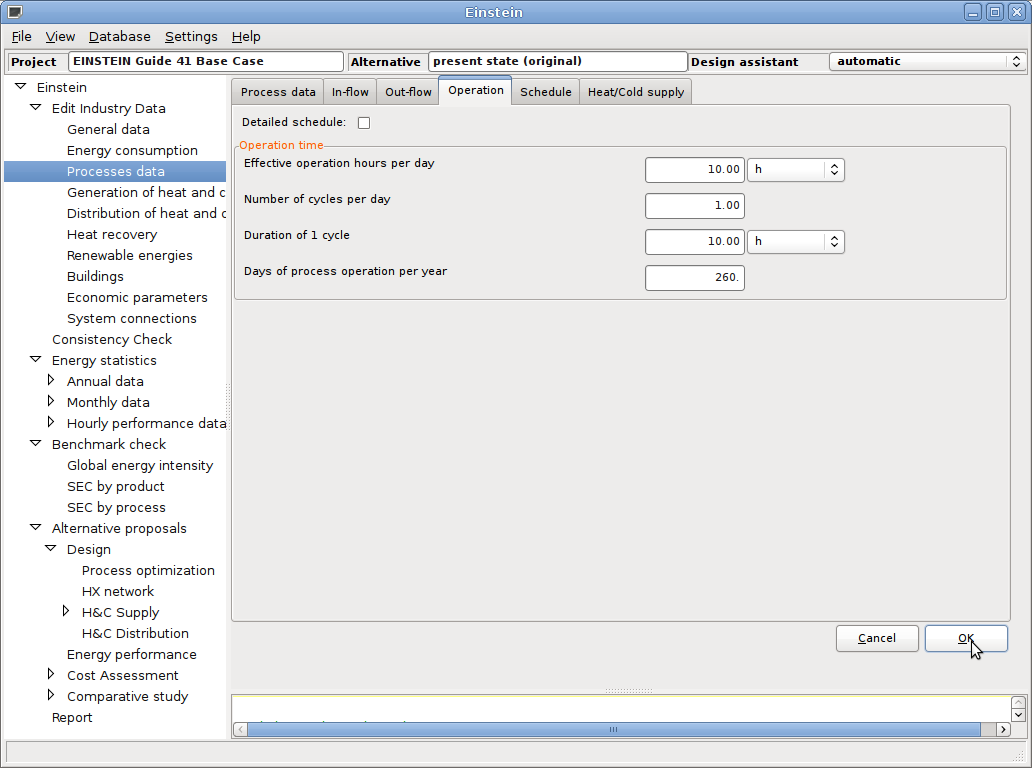

For each process the parameters defining the process operation schedules can be defined:

- continuous or batch process

- type of schedule

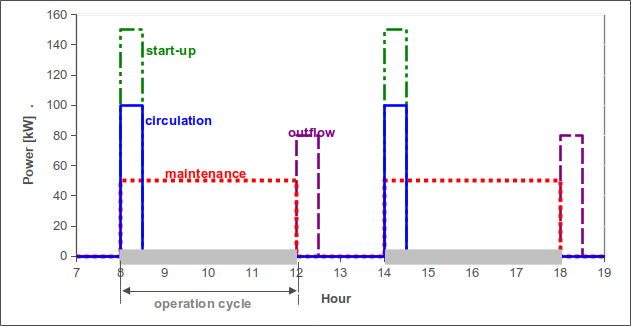

The duration of the start-up phase, and - for batch processes - also the inflow and outflow phase, by default is assumed to be 20% of the duration of the process operation cycle. For detailed schedules (see below) these parameters can be customised.

6.2.5.4.1. Process Type: Continuous vs. Batch Process¶

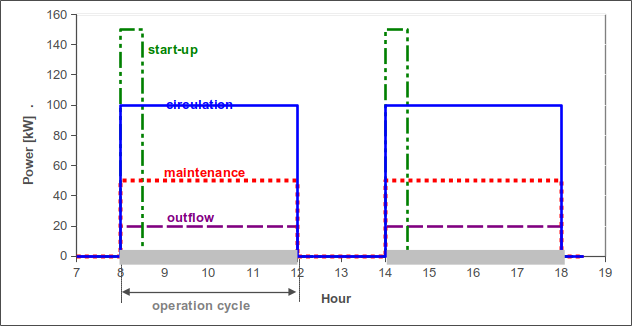

The selection of the process type (continous or batch) defines the sub-schedules of process in- and outflows with respect to the general process operation schedule.

schedules in a continuous process:

schedules in a batch process:

6.2.5.4.2. Schedule Type¶

- Simple Schedule

With only four parameters it is possible to define the times of activity of a process. The effective hours of operation per day, the number of cycles per day, the duration of each cycle and the days of operation per year ar these parameters. As the first three are actually redundant, it is enough to enter two of them.

- Detailed schedule

In a much more detailed fashion, the detailed schedule offers the definition of running times per week day and these weekly profiles may again be choosen for freely choosen periods within the year.

- Fit to Data (EINSTEIN *plus only)*

Process schedules can be obtained automatically by fitting to monitoring data. Define an appropriate set of monitoring data.