6.4. Benchmark Module¶

6.4.1. Why to use benchmarking module ?¶

This module is dedicated to the benchmarking of the energy efficiency of your facility. Benchmarking [1] refers to a structured process of comparing and analyzing business practices, in order to improve business processes by identifying, sharing and using best practices. The aim of this module is to enable evaluation of the energy efficiency of your company with the respect to the benchmarks or targets defined by the module. The module may be used to evaluate your energy use performance according to specific benchmark which refers to a range given by a minimum and maximum value (Bmin, Bmax) that describes the state of the art of existing industries in a given sector. The module also enables you to assess your performance according to specific target which refers to a target value for energy intensity or specific energy consumption that can be reached if economically feasible best available technologies are used. Where no explicit target values are given, the assumption is made that the industries with the best practice are those with energy consumption in the lower 10 % of the range between Bmin and Bmax. In that way you will be able to compare your business practice regarding energy efficiency to the best practices which refer to other business practices that are used to address a similar business process and produce superior results. Best practices [2] are documented strategies and tactics employed by successful companies. They can be identified from in-depth interviews with energy managers, thorough review of companies’ documents, analysis of literature and secondary sources.

6.4.2. How to view data for benchmarks in Einstein tool ?¶

Data on benchmarks in Einstein tool is selected from the existing BAT reference documents (BREFs) and other literature and sources, in order to form a basis for defining indicators and benchmarks/targets. Each benchmark in the database is equipped with Identifier number, NACE code, Unit operation code, Product code, Product name, eventual comments, Reference, Year (reference for economic data), Literature, etc. Several data may be entered for the benchmark dataset such as energy intensity (minimum or maximum value), etc.

The user can inspect benchmarks in the Einstein database by clicking on tab “Databases” and then on “Benchmarks” subgroup. The following window appears:

In the database, the user is able to add his owns benchmarking data (Add Row) or delete it (Delete row). Please note that for deleting the row it must first be selected. After changes are being made you need to press “OK”.

6.4.3. Which types of benchmarking indicators are used in Einstein tool ?¶

In the benchmark module three types of reference ratios are systematically used depending on the quantity used as a reference:

- Global Energy intensity

By clicking on “Benchmark check” > “Global energy intensity” the following window will appear:

Figure 99.99.1 This figure is the default figure “under construction”. here should be the figure title

As energy intensity we understand the energy consumption per monetary value of the product. The product value can be either expressed in terms of turnover (sales price) or in terms of production cost (approximately the sales price minus the industrial benefit). If not specified explicitly, the turnover (sales price) is used.

In the field “Benchmark(1): global energy intensity” a reference numbers related to the selected type of product or sector NACE code will display. The data on energy consumption specified by the user are graphically compared to the benchmark (for more information please see section “Benchmarking procedure in the Einstein module”). There is possibility to search for benchmarks according to specified criteria (this option is explained in the section “Searching Options in Benchmarking Module”)

- Specific energy consumption per product unit

The specific energy consumption (SEC) per product quantity is the energy consumption associated with the production line in question, with respect to the product quantity produced with it (measured in units, tons, liters, etc..; for example the total energy consumption per kg juice concentrate, energy consumption per liter of chemical product, etc.). By clicking on “Benchmark check” > “SEC by product” the following window will appear:

In the field “Benchmark(2): specific energy intensity (SEC) by product” a reference numbers related to the selected type of product or sector NACE code will be displayed. The data on SEC by product specified by the user is graphically compared to the benchmark (for more information please see section “Benchmarking procedure in the Einstein module”). There is possibility to search for benchmarks according to specified criteria (this option is explained in the section “Searching Options in Benchmarking Module”)

- Specific energy consumption per process (unit operation)

Besides of the ratios for final products, in the benchmarking module there are also found energy consumption ratios for unit operations. The specific energy consumption per quantity of processed intermediate product is the energy consumption associated with this unit operation with respect to the product quantity (measured in units, tons, liters, etc.; e.g. the energy consumption per kg or liter of distilled solution). Where these ratios are found, the reference base is mentioned (e.g. in a drying process the energy consumption can be indicated per kg of humid product or kg of dry product, which can lead to very different numeric values).

By clicking on “Benchmark check” > “SEC by process” the following window will appear:

In the field “Benchmark(3): specific energy intensity (SEC) by unit operation” a reference numbers related to the selected type of product or sector NACE code will be displayed. The data on SEC by process (unit operation) specified by the user is graphically compared to the benchmark (for more information please see section “Benchmarking procedure in the Einstein module”). There is possibility to search for benchmarks according to specified criteria (this option is explained in the section “Searching Options in Benchmarking Module”)

6.4.4. Benchmarking procedure in the Einstein module¶

Comparisons of energy efficiency of your company is made by comparing the actual value of specific indicator I (e.g. specific energy consumption per tonne of product – SEC) with a reference benchmark/target Iref that is based on the given sector structure. This means that both the actual I and the reference Iref are similarly affected by changes in sector structure.

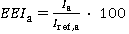

In this benchmarking module, reference target Iref is defined as the benchmark/target taken from the reference documents on best available techniques or from best commercially operating plant observed worldwide (also referred to as “best plant”). The difference between the actual I and reference Iref is used as a measure of energy efficiency, because it shows which energy efficiency level would be achieved in your company when a particular plant technologies would be used. The smaller the difference, the better the energy efficiency is. The relative differences between actual I and reference Iref can be compared between companies. In the module, this is done by calculating an energy efficiency index (EEI) as presented in Eq. 1: the ratio between actual I and reference Iref. If only best plant technology is used within a sector, the EEI would equal 100. An EEI of 105 means that I on average is 5 % higher than the reference level, so that 5 % of energy could be saved at the given process structure by implementing the reference level technology.

in which EEIa is the energy efficiency index for company/sector a, Ia the specific indicator of energy consumption for company/sector a, Iref, a the reference benchmark/target for company/sector a.

6.4.5. Searching Options in Benchmarking Module¶

Finding benchmarks for industrial (sub)sector

If you are interested in all available benchmarks for specific industrial sector, the easiest way to find them is by using the search button »find benchmarks«. You can then choose to search for benchmarks across some industrial sector by selecting NACE codes. Further, you can specify to search for your benchmark according to minimum and maximum volume of process and according to specified time period (min and max reference year).

Benchmark module identifies industrial branches by using the NACE codes. These codes represent the statistical classification of economic activities within the European Community. Users of the module can search within the following sectors:

Food, Milk and Drink Industry (NACE Code D15)

Pulp and Paper Industry (NACE Code D21)

Iron and Steel industry (NACE Code D27)

At the moment, only the three above-mentioned sectors are implemented, with the possibility to include other sectors or groups in the future. Nevertheless, the user may add his own benchmarking data in the benchmarks database.

In industrial production of goods, a unit operation is a basic step in a process. For example in milk processing, homogenization, pasteurization, chilling, and packaging are each unit operations which are connected to create the overall process. A process may have many unit operations to obtain the desired product. The benchmarking module allows user to search for energy benchmarks for several process unit operations within specific manufacturing process.

References:

| [1] | Source: The European Benchmarking Code of Conduct |

| [2] | California Best Practices Project Advisory Committee (2004) National Energy Efficiency Best Practices Study, Volume M – Methodology, Kenneth James (Contract Manager).Quantum Consulting Inc. |